At Nordson EFD, they understand that every automation need is unique, whether a customer is seeking a flexible solution or a specific application. Their extensive range of automated dispensing systems ensures there’s a perfect fit for diverse manufacturing requirements. They offer a variety of robots, from cost-effective models that deliver exceptional performance to high-performance options designed for demanding tasks.

Nordson EFD provides a range of fluid dispensing solutions, from hand-held to fully automated systems, which can be scaled with a customer’s evolving production process. A typical user journey begins with an R&D engineer developing a prototype, often using manual methods such as a squeeze bottle or a brush to apply fluid for bonding, coating, or sealing components. However, as production scales up, challenges often emerge that cannot be resolved with simple tricks. Issues with repeatability and accuracy become prominent, and variability depending on operator skill can lead to inconsistent outcomes—especially when moving from producing a few dozen to thousands of parts per day.

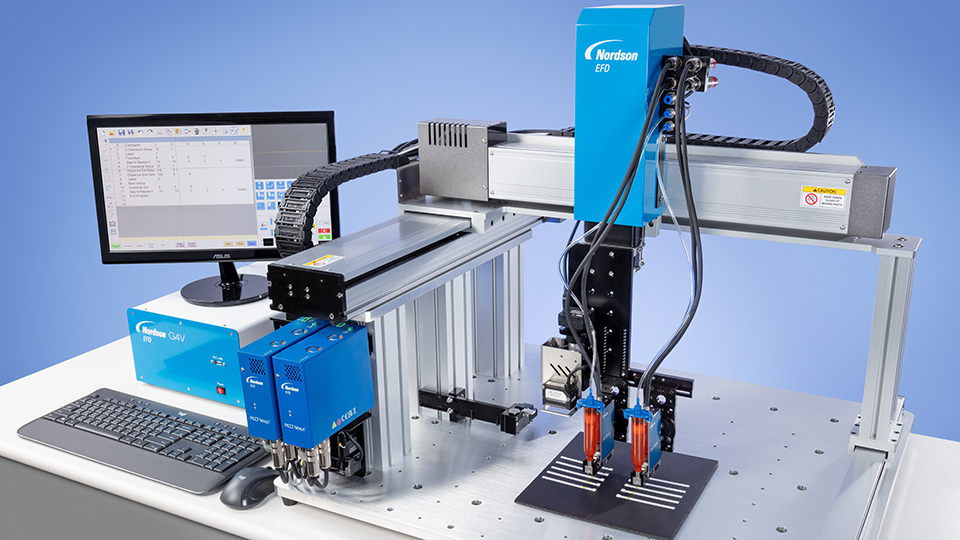

To address these challenges, Nordson EFD offers advanced robotic dispensing solutions equipped with intelligent software and integrated vision systems. Their DispenseMotion™ software simplifies complex fluid dispensing with user-friendly, point-and-click programming, enabling quick setup and minimal training. Coupled with integrated vision and optional AOI software like OptiSure™, these systems provide precise motion control, deposit verification, and real-time quality feedback for critical applications. Additionally, optional height detection sensors—laser or mechanical—ensure accurate fluid placement across varied surfaces, while automatic tip calibration maintains deposit accuracy after tip changes, all without reprogramming.

Their dispensing robots are engineered to improve precision and ensure repeatability across multiple applications. They are compatible with all syringe-based and valve-based systems, making them versatile for inline and batch tasks such as potting, filling, sealing, and bonding. The robots support complex movement, integrated vision, and post-dispense inspection, delivering consistent results on uneven surfaces and improving overall product quality.

Nordson EFD’s robot selection includes 3-axis and 4-axis models, such as the RV Series for Z-axis rotation, the GV Series for conveyor-fed production, and several Cartesian robots (E, EV, PRO, ProPlus) tailored to specific needs. Their systems support features like height detection (laser or mechanical), automatic tip calibration, and guarded enclosures for operator safety—ensuring fast, safe, and reliable operation.

When partnering with clients, Nordson EFD’s specialists assess specific requirements—movement complexity, vision system needs, inspection capabilities—and recommend the most suitable automation solution. Their portfolio features various configurations designed to meet precise dispensing demands, backed by expert validation and comprehensive training resources. Their goal is to help customers find the ideal, scalable automation system that enhances efficiency, accuracy, and product quality.