What is Eck®?

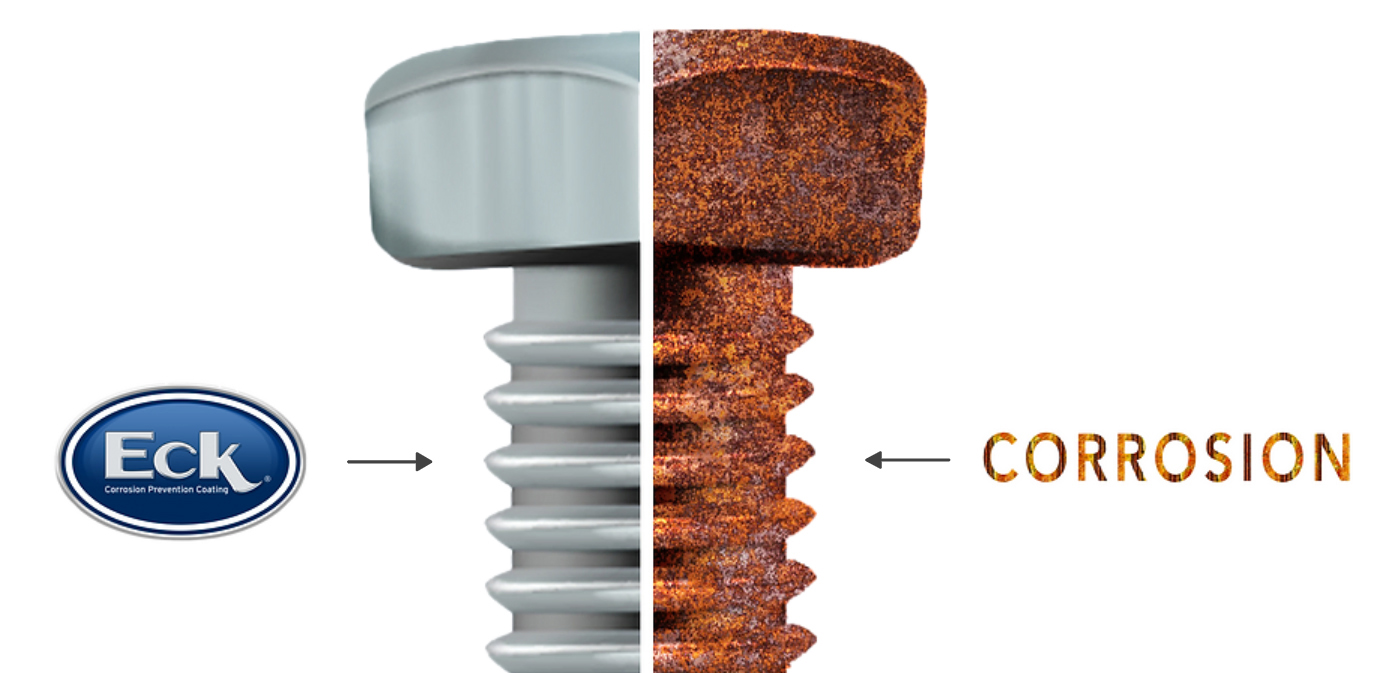

Patented since 1998, Eck® is a petroleum-based, zinc-rich dielectric coating engineered to prevent galvanic corrosion, magnesium chloride corrosion, calcium chloride corrosion, rust, and fastener seizing.

By creating a protective barrier between dissimilar metals, such as aluminium and stainless steel, Eck® stops electrolysis before it starts. Unlike traditional coatings, it never fully dries, maintaining a lasting seal that locks out moisture and corrosive elements. Find out more.

Eck® eliminates the need for barrier tapes, coated hardware, or spacers and washers, offering the ultimate protection for both painted and unpainted surfaces. It also functions as a dielectric grease, making it ideal for use with electrical connectors. Rigorously tested in both laboratory conditions and real-world environments, Eck® has successfully passed a 4,000-hour corrosion resistance test, proving its unmatched durability.