This distinct chamfered design allows the rings to wedge precisely into a compatible groove, eliminating end play and securing the retained part.

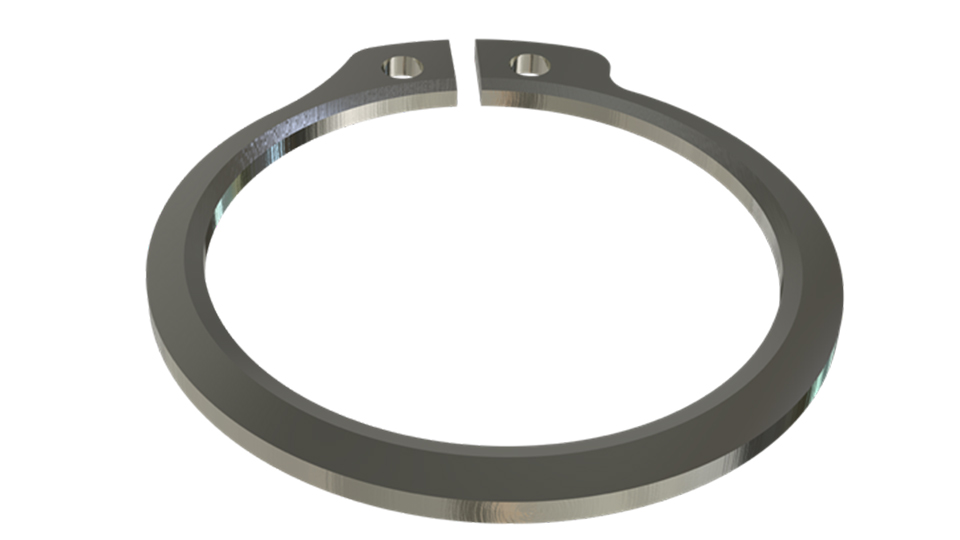

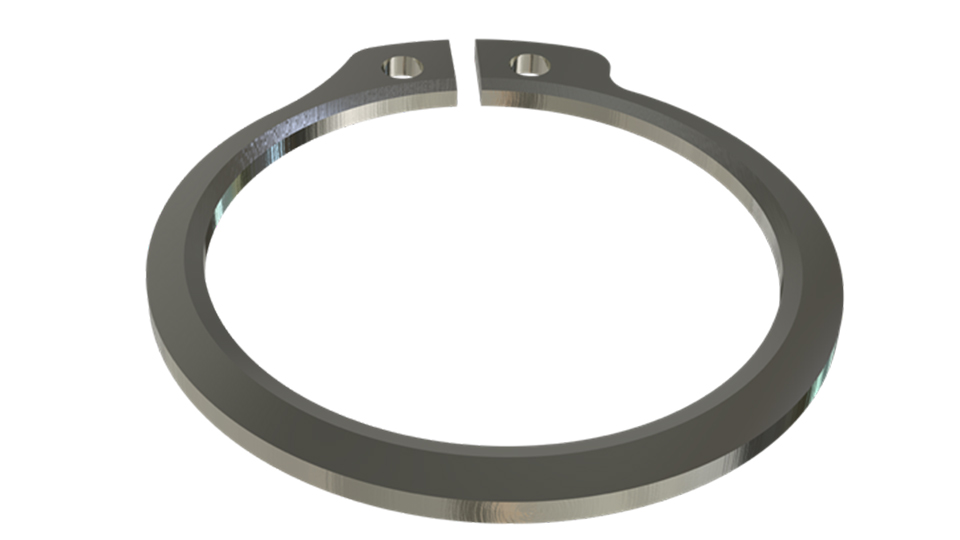

Beveled retaining rings, also known as bevel-edged snap rings or circlips, are designed to securely fasten parts onto shafts or within bores. Unlike traditional retaining rings which have two distinct faces, top and bottom, these rings feature a 15-degree bevel and a narrower edge —either along the outer periphery for internal rings or along the inner edge for external rings. This distinct chamfered design allows the rings to wedge precisely into a compatible groove, eliminating end play and securing the retained part.

When selecting the right beveled retaining ring, factors such as assembly type, available space, both dynamic and axial load requirements, take-up or noise elimination are crucial considerations. Ensuring the correct groove location and understanding these factors are essential for precise fit and reliable operation. These rings are utilized across various industries for their ability to maintain part integrity under demanding conditions.

Rotor Clip’s Beveled Retaining Rings

Rotor Clip offers a comprehensive range of beveled retaining rings designed to meet your specific requirements. Our internal VHO and external VSH variants are available in sizes ranging from 1 to 10 in (25.4 to 254 mm), ensuring a solution for different applications across nearly every industry.

- VHO (Internal Beveled Housing): These rings have a beveled outer edge and are designed for use in housings and bores[LP1] .

- VSH (External Beveled Shaft): These rings have a beveled inner edge and are designed for use on shafts and pins.

Take-up solutions are available for applications under 1". Contact our technical sales department to learn more now.

Advantages

Beveled retaining rings offer several key benefits that make them stand out from other types of retaining rings / snap rings:

- Improved Retention: The chamfered edge of beveled retaining rings provides a secure grip within the groove, effectively preventing movement even under dynamic conditions.

- Absorption of End-Play[LP1] : Beveled retaining rings excel in absorbing axial movement (end-play) within assemblies, reducing noise, vibrations, and enhancing operational smoothness and part durability.

- Improved Load Stability: The 15° beveled edge [FE2] allows the ring to distribute load more evenly across its circumference, reducing the risk of deformation or failure under high stress.

- Optional Visual Orientation[LP1] : On some sizes, an asymmetric lug can be added to beveled retaining rings, providing a fast and easy way to identify the beveled side. This can streamline installation and reduce the risk of improper orientation by operators or vision systems.

Application Examples

Beveled retaining rings excel across diverse industries, such as:

- Automotive: Beveled retaining rings enhance various applications, including transmissions, securing gears, and bearings. By evenly distributing loads and preventing axial movement, they ensure smooth operation even under high torque and rotational speeds, which helps reduce noise and vibration and extends bearing life.

- Aerospace: These rings play a critical role in aerospace actuators, such as those in flight-control systems. Their ability to maintain a secure fit and enhance stability ensures precise movement and safety during critical maneuvers.

Our beveled rings are engineered[FE1] from a variety of high-quality materials and finishes, and subjected to meticulous quality checks and testing, Rotor Clip provides Application Driven Solutions® for your application needs,[FE2] every time. We are dedicated to being your trusted partner, offering engineering support throughout the entire development process to ensure the best solution for your specific requirements.