Bonding tasks in the manufacture of electronic components consistently present development and construction engineers with extraordinary challenges: The components are becoming ever smaller and more powerful, but also more sensitive. For such applications, double-sided adhesive tapes are recommended, which are available on the market on rolls, in the form of sheets or die-cuts. Electrically- and thermally-conductive adhesive tapes are of particular importance.

The amount of electrical current depends significantly on the physical parameter of electrical conductivity of a material such as metals, salts, solutions, but also for adhesive systems. As can be seen from this, the current I depends on the potential difference U and the electrical resistance R.

As a manufacturer of electrically-conductive adhesive systems, we cannot influence the potential difference U, as it depends on the application. The only point at which we can really be effective is to change something in the electrical resistance R, i.e. in the adhesive product itself.

If we break down the electrical resistance R further, this depends on the surface A, the length l and the specific resistance p.

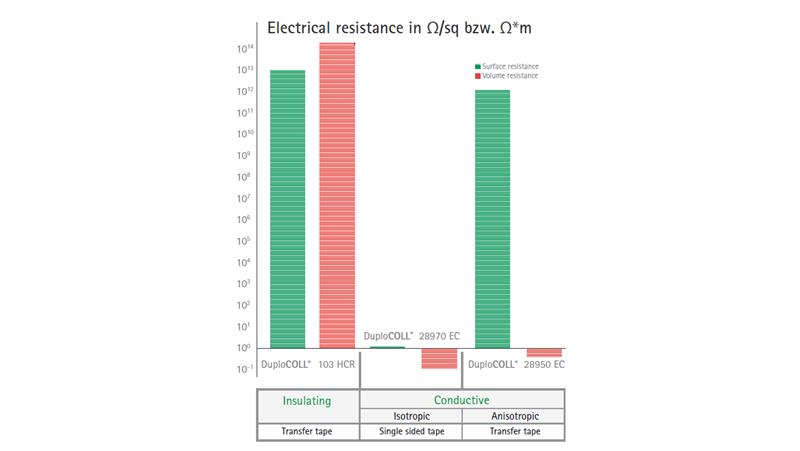

However, the specific resistance p is further subdivided into isotropic and anisotropic parts: the anisotropic part determines the electrical resistance in the volume (z-axis) whereby the isotropic part of a product covers the resistance in all three axes (x – y – z).

Which connection exists between electrical resistance and electrical conductivity?

The electrical conductivity of a substance is the inverse value of the electrical resistance of a product and is specified in Siemens (S): Electrical conductivity (S) = 1/electrical resistance (R); 1S = 1 / 1Ω

Depending on its electrical resistance, materials are described as conducting, conductive, antistatic or insulating. Since adhesive systems mostly consist of mono- and polymers, these are in principle to be regarded as electrical insulators.

If we now compare conductive and non-conductive adhesive systems, we observe that the electrical conductivity depends on the type, size, shape and volume of the filler materials used.

Considering all of these demands on adhesive bonds, electrically conductive, adhesive tapes such as the Lohmann DuploCOLL EC (EC = electrically conductive) range are continually gaining importance.

These ensure that signals and electrical energy – depending on the application – are conducted quickly and with little resistance from one point to another.

An example: for the field of printed electronics, rigid clamp or screw connections are still used today, which reduce the mechanical flexibility in the application. In this case, an alternative could be an adhesive tape solution that is anisotropic (conductive only in the z-axis).

Even for applications that involve the bonding of the smallest areas, such as a ground point in a sensor/actuator, an electrically conductive adhesive tape can make the use of an additional cable superfluous.

For this reason, Lohmann decided years ago to develop a new product range – the DuploCOLL EC range. The particular advantage of the range is its easy handling. With light pressure, the product clings very easily to the surface of the substrates. It significantly reduces the contact resistance between the two substrates and conducts the electrical signal from one point to the other.

Within this special range of adhesive tapes, in addition to the transfer adhesive systems (adhesive tapes without a carrier system for reinforcement), we also offer single-sided or double-sided adhesive tapes.

The Lohmann Bonding Engineers have not only developed this adhesive system, they also offer customers the complete subsequent processing along the entire value chain. Depending on customer requirements, the product is brought into its specific size, dimension and geometry using innovative converting and die-cutting methods. Thus, this gives our customers the freedom they need for further processing and in the application process.

This article is an edited version of a Lohmann DuploCOLL EC white paper.