Encapsulation is performed to protect bare semiconductor dies that have been attached to a substrate. It also protects any wire bonds for electrical connections between the top surface of each die and the substrate.

For high reliability applications, heat-cured adhesives are used as opposed to light-cured. This is because the chemistry of a heat-cured encapsulant tends to have a low coefficient of thermal expansion (CTE) as well as a high glass transition temperature (Tg) – both of which assure a long operating life in the field.

By far the biggest advantage of a heat-cured adhesive is a wide operating temperature range. Military applications typically require an operating temperature range of -55 to 150°C. Many other harsh environment applications, such as medical and industrial, have adopted this range too.

In addition to having to cope with the temperature extremes of the environment, there is also the issue of generated heat. For example, all heavy-duty solid-state power switching modules used in aerospace, automotive and power grid applications contain a silicon carbide (SiC) or gallium nitride (GaN) die, or chip portion. Even with efficient thermal management in place, die temperatures can easily exceed those expected in military applications.

Most high-reliability applications also call for the highest level of moisture resistance (JEDEC’s MESL 1: unlimited floor life at 30°C and less than 85% relative humidity). This is because if moisture gets into the encapsulant, expansion during high-temperature cycling (‘popcorning’) can damage the chip. Damage can also be caused, over time, by outgassing, and many applications demand that chip encapsulants have measured ionic impurity levels of less than 10ppm.

It is also worth noting that adhesives used for high-reliability chip encapsulation are also used for protecting sensitive sensors in harsh environments and industrial applications because, in addition to the above benefits, they are also resistant to oils and most chemicals.

SVHC

Much is required of a chip or sensor encapsulation adhesive to ensure high reliability, and the properties that make it fit for purpose are down to its chemistry and, specifically, the inclusion of compounds now formally classified as ‘substances of very high concern’, or SVHCs, because they are hazardous to health and/or the environment.

The European Chemical Association (ECHA) is constantly reviewing and working towards banning the use of SVHCs, not just in adhesives but also in paints, detergents, cleaning products and so on.

For chip encapsulation adhesives, the main compound in question is an anhydride epoxy called hexahydro-4-methylphthalic anhydride.

All SVHCs are regulated under the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH), an EU regulation that came into force on 1 June 2007 and replaced multiple European directives and regulations with a single, unified system. One of REACH’s goals is to make “…the people who place chemicals on the market (manufacturers and importers) responsible for understanding and managing the risks associated with their use.”

If – or more likely when – the ban goes ahead, it will force manufacturers based in Europe to cease making products containing even small traces of SVHCs. Or, to put it another way, this is not like the lead-free solder directive introduced a few decades ago. That ban was placed on the users, not the manufacturers.

Aware of the likely ban of SVHCs, some manufacturers have taken the opportunity to develop products that will not only be fully compliant, but which also have properties that make them even more suitable for harsh environment applications. And the results so far are positive.

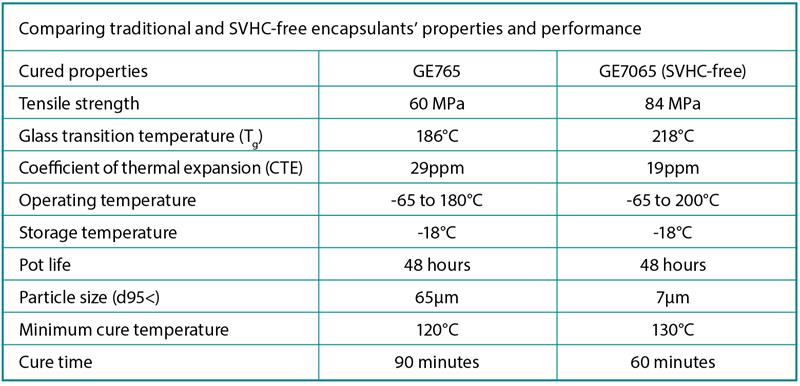

For example, Delo Monopox GE765 is a popular GlobTop encapsulant. It contains hexahydro-4-methylphthalic anhydride which, as mentioned above, is an SVHC. The SVHC-free alternative for this encapsulant is the recently announced Delo Dualbond GE7065. The table below compares the cured properties of the two adhesives.

Of those properties, the lower CTE and higher Tg and operating temperature make the SVHC-free one suited to applications where heat resistance is a must. Benefits are also gained during the encapsulation process. In particular, GE7065 is light-fixable, and exposure to UV light will freeze the adhesive in place, allowing the board/substrate to be moved without risk of slumping of the GlobTop dome.

BE PREPARED

The ban is almost certainly coming, and a decision was meant to have been made by ECHA in June 2020 but was delayed by COVID-19. That said, there is no need to panic, because ECHA will provide notice. Also, as demonstrated above, SVHC-free products are available now.

Lastly, improvements in SVHC-free adhesives have been made on the dam & fill front too, and again, greater in-field and manufacturing benefits have accompanied the change to SVHC-free encapsulants. See also a fact sheet which contains links to ECHA and REACH, available via www.is.gd/miruco.