Reducing the in-place fastener cost for moulders with TRI-STEP™.

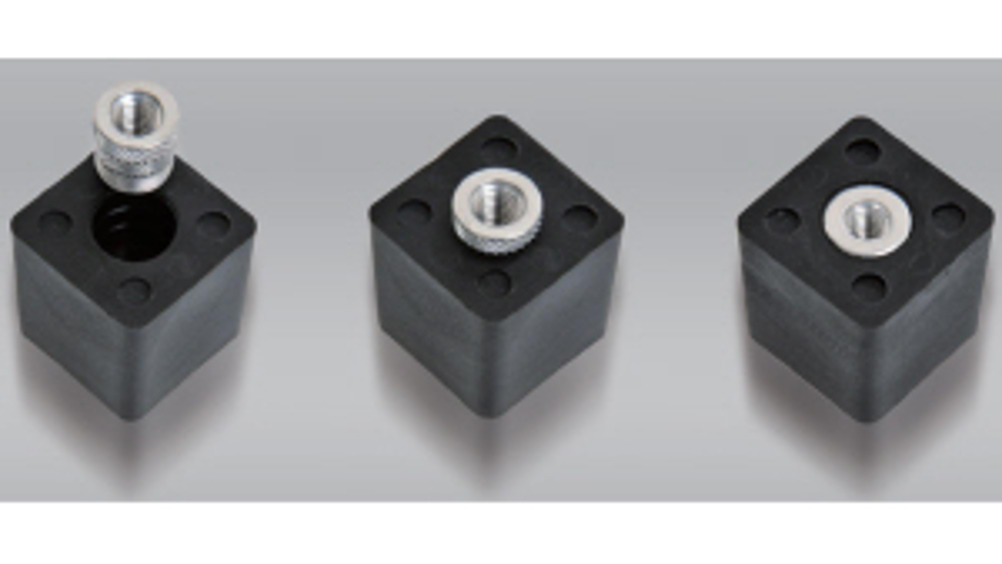

TRI-STEP™ is a unique patented three stepped threaded insert and mating hole combination, designed for heat or ultrasonic installation into thermoplastic materials. Using TRI-STEP™ enables plastic moulders to reduce insert travel time on insertion by up to 60%, typically offering savings against tapered inserts such a 2 second reduction in dwell time. TRI-STEP™ also eliminates insert spring-back.

The aluminium version of TRI-STEP™ has a 40% higher thermal conductivity compared to brass or steel, which reduces contact heating time and reduces cooling time, thus giving improved height stability. This aluminium option also gives a 66% weight reduction compared to equivalent brass inserts.

The design incorporates two diameters of opposing helical knurls and a series of annular vanes.

The TRI-STEP™ range includes a high strength oversize design and a thin walled design that is available in two standard lengths. Both ranges provide high performance, excellent location, reduced insertion time and low in-place cost.