Why do gaps occur in large structures?

When dealing with large composite structures, there are a few reasons that gaps and voids occur:

• There tends to be difficulty in keeping narrow component part tolerances because assemblies need a bit of wiggle room to fit together. Opening tolerances assists in having less rework and post finishing before heading to assembly.

• With composite bonding, manufacturers see mold variances and twisting of the parts once removed from the mold. These occurrences can create gaps of varying sizes from part to part when attempting to do final assembly.

Both of these variance types can show up in many different places on the component, and some engineers purposefully allow for these variations in their designs, to lessen the amount of rework needed for each part. Purposeful gaps and voids are most often designed in corners and seams, where the parts are joined together.

Why is filling gaps in large structures important?

These gaps, planned or unplanned, must be filled with something to have a safe and stable joint between the pieces. Any vibrations in an area with empty gaps and voids can cause cracking and complete failures of the joined structures. Large gap filling adhesives are an excellent choice to reduce the risk of empty voids and joint failures by combining bond strength and gap filling into one product.

What types of adhesives are used to fill gaps in large structures?

There are three main types of adhesives seen in the large structure bonding world: epoxies, methyl methacrylate adhesives (MMAs), and polyurethanes. There are many differences in these types of adhesives, however, a few of the differences are most important to consider when picking an adhesive as a gap filler.

Epoxies tend to have very high strengths. Because the strength is so high, the cured adhesive is often very rigid. This rigidity displays itself in “brittleness” that leads to finished structures with a lower resistance to vibrations.

Polyurethanes, on the other hand, are much more flexible and much more resistant to vibrations and impacts. These qualities, however, lead to lower strengths overall. Gaps filled with polyurethane can be easier to pull apart.

Methyl methacrylate adhesives, or MMAs, bridge the gap between epoxies and polyurethanes. These adhesives have high strengths, although not as high as epoxies. They also have high elongation or flexibility, but again, not as high as polyurethanes. With MMAs, users experience strengths that are high enough for most bonding applications, as well as a high enough elongation to withstand the lifetime of high vibration parts. Due to the combination of high strength and high elongation, MMAs are the ideal adhesives for gap and void filling.

How do I select an MMA for gap filling?

There are a few aspects of MMAs that need to be kept in mind when choosing an adhesive for gap filling. First, designers should note that methyl methacrylate adhesives are two-part adhesives that cure using an exothermic reaction, where heat is released during the curing process. The amount of heat is often fine-tuned during the selection and development of the adhesive. When choosing an adhesive for large gap filling applications, make sure to check the technical documents to ensure that the adhesive was designed for large bead and gap filling. If bead size is not considered, the heat from the reaction can get quite high and cause several issues in the bond line. These issues can be boiling or print through of composite parts, leading to more post or finishing work.

The second thing to remember with MMAs for gap filling is that many gaps tend to see high rates of vibration. Ensuring that you choose an adhesive that is vibration- and/or fatigue-resistant will ensure a stable and lasting bond throughout the lifetime of the finished assembly.

Another thing to keep in mind is the placement of the gaps within the design of the assembled structure. Often, vertical surfaces require gap filling. The adhesive, therefore, must be able to cling onto the vertical wall or surface in large beads without running down, or sagging, before the parts are together and the material is cured.

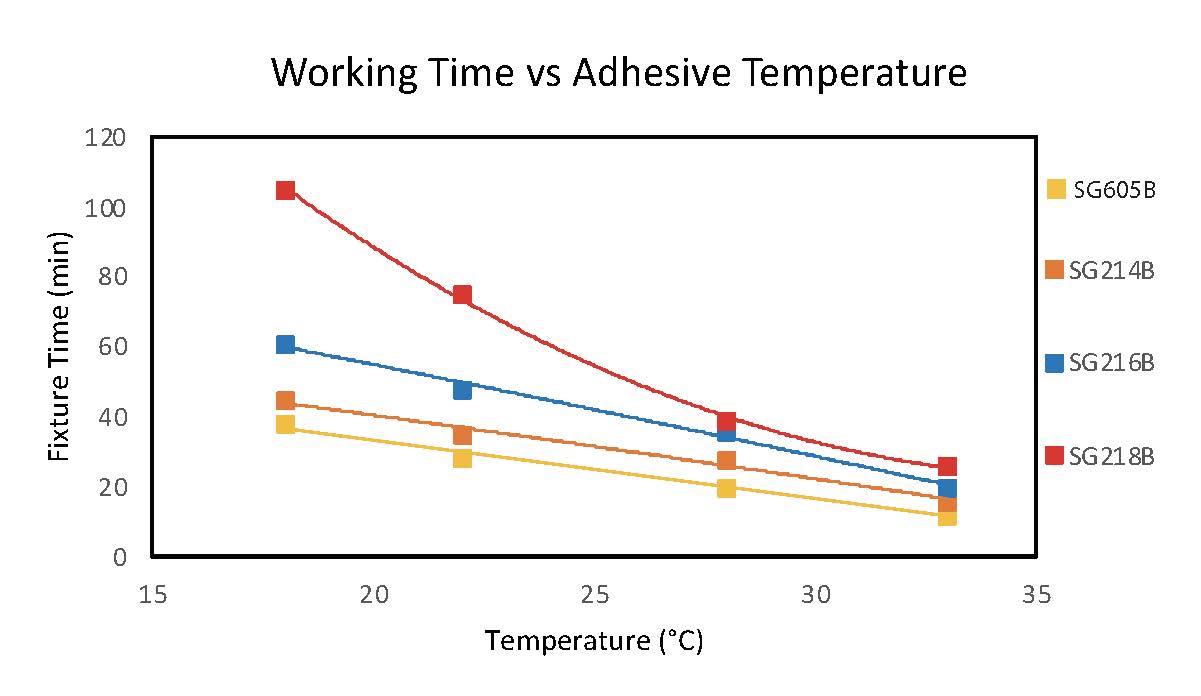

A final consideration for choosing a gap filling adhesive is the end user’s environmental temperatures. For example, in the winter in Florida, the temperatures are high with only a few cold days. But when summer comes, temperatures can spike much higher than 100°F (38°C). With MMA adhesives, the reaction time during application of the adhesive will change based on the outside temperatures. In Figure 1, we can see that as the outside temperatures rises, the fixture or working time of the mixed adhesive drops quickly. If an end user is applying large amounts of adhesive on a large part in a very hot temperature, they will need as much working time as possible to lay the adhesive and get the parts together.

How does temperature affect gaps filled with adhesive over the long term?

Adhesive manufacturers get a lot of other questions about parts being exposed to high temperatures after the material is cured. For the most part, MMA adhesives handle environmentally high temperatures very well. In some situations, however, issues can arise if the material is subjected to extremely high temperatures seen in processes such as paint bake and powder coat cycles. If the material cannot withstand these heats, the adhesives will melt or degrade. Always check with your adhesives manufacturer before running parts through these processes.

How are adhesives tested for their ability to fill gaps in large structures?

When designing MMA adhesives, chemists conduct several tests to ensure the material does not boil during its exothermic reaction and can be stacked into the larger bead sizes needed for gap filling. Large weight reactivity testing is done to show the true exotherm created when a large mass is used at end use customers. Large beads are also created, either by hand or running the material through a meter mix machine. These beads will show if any boiling occurs and are used to ensure there is a solid, hard cure throughout the entire length of material. Laboratory technicians will also apply these large beads on a vertical surface to measure how much the material will slide down a slick surface, or sag. Once the material is cured, the bead will be cut in half to inspect the inside of the bead, to check for internal boiling or air pockets. These voids in the cure adhesive beads may introduce a weak point in the gap fill leading to a higher chance of failure than a section with no air present.

Once these tests are passed, the material will then go through physical testing. Tensile and elongation measurements are run using ASTM standard testing. Running these tests shows true data about how strong and flexible the material will be in the field. Also using an ASTM standard, aluminum lap shear samples are bonded and run through fatigue testing. Fatigue testing shows how resistant the adhesive is to vibrations.

Are there adhesives specifically designed for gap filling in large structures?

SCIGRIP Adhesives® has designed multiple adhesives specifically for gap and void filling and bonding. These three gap filling adhesives (SG230HV, SG2000, and SG350L) have different qualities to address a large variety of gap filling applications.

• The SG230 series is a 10:1 mix ratio MMA adhesive. This adhesive has several different working time offerings to ensure the user has enough time to lay the adhesive and bring large parts together before the adhesive begins to cure. With the capability to fill gaps up to 1.5 inch (39mm), as well as stacking and non-sag characteristics, and fatigue and vibration resistance, the SG230 series is a great choice for large project gap filling.

• The second adhesive SCIGRIP offers in the gap filling line is the SG2000. This adhesive has many of the same characteristics as the SG230, with the main difference being the mix ratio. SG2000 is a 1:1 non-critical mix ratio gap filler. Some assemblers prefer to have a 1:1 ratio material due to greater simplicity in controlling and locking out the pressures on a meter mix machine. With a single working time, this adhesive is also great to fill gaps up to 1.5inches (39mm) and also has non-sag and fatigue resistant qualities.

• The last product in this line is the SG350L, currently being manufactured at SCIGRIP’s UK manufacturing facility. This adhesive can address even larger gaps, up to 5.9 inches (150mm) without boiling. With high elongation and superb fatigue resistance, the SG350L is a great choice for very large gaps.

In summary: using adhesives to fill gaps in large structures

While gaps are a regular occurrence in structure design and assembly, particularly for composites, adhesive manufacturers have developed solutions to fill them effectively. Engineers, designers and assemblers should carefully review their application, environment, and assembly processes to understand their needs. Often an MMA adhesive is a good choice, especially for large gaps.