Conformal coatings were originally developed for military, aerospace, and marine applications but have been increasingly used in a broader base of telecommunication, computer, automotive, consumer, industrial, and instrumentation applications to increase product quality and performance.

Even though conformal coatings are excellent protective materials they can also suffer from defects that affect their performance including air bubbles, cracking, delamination, de-wetting, pinholes, and tin whiskers. As a result, PCB rework may be necessary for high-value boards.

Ease of rework and removal are linked to the resilience of a coating to specific factors in the operating environment. Light-cure coatings offer high resistance to heat, abrasion, and chemicals, and may be considered more difficult to remove. Easier rework coatings are less resistant to heat, abrasion, and chemicals.

Three techniques are typically used to remove cured, cross-linked conformal coatings: mechanical, thermal and chemical methods. It’s important to consider the effect of the rework/removal method on solder masks, components, and assembly materials prior to choosing the method.

Mechanical removal involves scraping or cutting the conformal coating. It may be an option for some applications and is easier with thicker, more flexible coatings. Pressurised abrasive systems are often used to safely remove cured coatings. The abrasive is easily removed from the surfaces without danger to the components or to the reworking process. This technique is fast, cost-effective, and environmentally clean. It also enables you to selectively remove the coating from a specific targeted area, while causing no damage to the surrounding components.

Two thermal heat removal techniques are possible to remove cured conformal coatings, depending upon the temperature sensitivity of the components located on the printed circuit board. These include heating the entire board to strip the coating at once or using a hot-air de-soldering tool or a solder gun to remove spot coatings.

Chemically removing cured conformal coating requires treating localized areas or immersing the coated board with a chemical stripping solution.

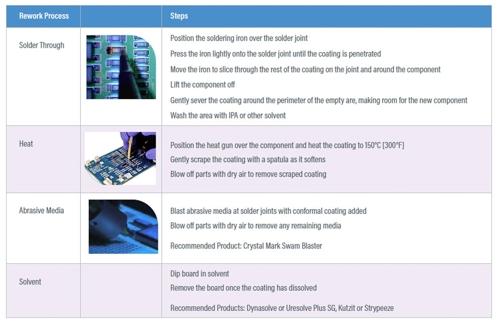

The chart below illustrates four methods of reworking conformal coatings.

For more information, see https://dymax.com/resources/news-and-media/blog/conformal-coating/how-to-rework-remove-conformal-coatings