When working in the manufacturing and engineering industry, the production and maintenance of machinery is vital when ensuring all employees are working in a safe environment. Exposure to vibrations and loud noises within the workplace, which is commonly caused by imbalance, misalignment, loose parts or wear and tear of a machine, can lead to major health problems such as Hand Arm Vibration Syndrome (HAVS), hardness of hearing and even deafness. The Health and Safety Executive receive 3,000 new claims in relation to HAVS every year.

In the UK, the Control of Vibration at Work Regulations 2005 came into force on the 6th July 2005, to protect workers from risks to health from vibration. Nearly 2 million people in the UK are at risk of developing HAVS whilst at their place of work. Vibration within machinery can also affect productivity, as well as lead to costly maintenance and factory downtime. Making improvements to all vibrating machines will reduce the chances of employees developing HAVS and improve overall performance.

A healthy worker is a happy worker

As the old cliché goes, your most important asset is your workforce. In the case of reducing vibration around the workplace, this couldn’t be more true.

Depending on the frequency range and interference frequency (the frequency to be absorbed) of machine vibrations, problems with health and concentration can occur during prolonged exposure, as well as reduced staff productivity. If employees are working with machines generating vibration, they have the risk of developing work-related musculoskeletal disorders, stress-related health effects, noise-related hearing loss and even changes to neurosensory function.

Damage from HAVS is more commonly known to affect the hands and arms and can cause the inability to carry out complex tasks, as well as triggering painful finger blanching attacks in cold weather. HAVS develops slowly and can also affect the whole body, but once a worker develops the disease it becomes a permanent condition.

Accidents and injuries caused by vibration can be extremely debilitating and permanent, but most importantly – they are preventable. Ensuring anti-vibration components are installed in all machines will help reduce any health or production issues for all workers in this environment.

Keep on top of machine maintenance

Machine vibrations affect more than the people who operate them, they can also have a significant impact on the performance of a machine. Small vibrations can adjust the movements inside the machine, which may cause the machine to produce a defected product or output. Continuous vibration will cause machinery to become increasingly difficult to maintain, leaving parts that need to be configured or readjusted.

Of course, some machines need to vibrate in order to operate effectively. However, using anti-vibration components can help dampen vibrations in certain areas of the machine, reducing the chance of impacting other machines/components in the vicinity.

Machines will also begin to wear down over time with exposure to any level of vibration. As vibration waves travel through the machine it will adjust the position of the components inside and outside, causing friction and thus the wearing down of the machine’s parts.

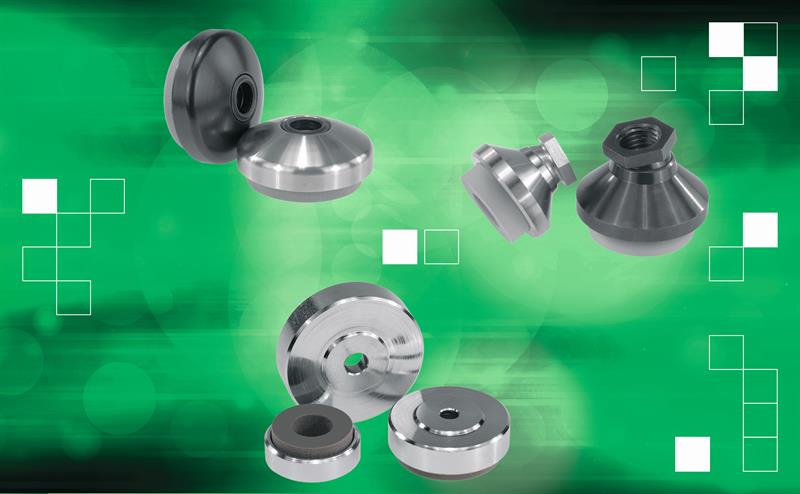

With friction also comes heat, which may result in parts of a machine overheating gradually over time. This means a potentially shorter service life of the components within the machine, higher frequencies of needing to maintain or replace components, and a higher price tag on the lifecycle of the machine. Reducing vibration waves produced by a machine can be simple however, such as the addition of swivel feet, machine feet and rubber buffers which are designed to absorb vibrations, cushion shocks, reduce acceleration and structure borne noise from manufacturers and suppliers such as norelem.

Unnoticed vibration can cause unscheduled downtime as well as excessive power consumption which may damage the product’s quality. If anti-vibration components are used correctly, they are excellent at reducing the transfer of vibration and noise. For example, when using norelem’s swivel feet with an interference frequency of 44Hz, it has an absorption effect of 69%.

Extend the life of your machine

Ensuring machinery is working efficiently is essential when operating a manufacturing or engineering plant. When vibrations are present it’s always good to consider different ways in which you can reduce the effects of wear and tear on the machines. Machinery and tools can last longer when designed with anti-vibration components, increasing its service life significantly.

Rubber buffers can isolate and dampen the vibrations in a variety of applications, including aggregates, motors, compressors, pumps, inspection machines and mechanical components.

These properties allow them to be used to absorb vibrations when machines, mechanical components and worktables are mounted and anchored to them. Swivel feet are also another standard component that can be used to reduce the strength of a machine’s vibration. Effective vibration absorption is dependent on the interference frequency and the natural frequency of the absorption unit.

Every spring-loaded mass such as a machine or piece of equipment that is standing on swivel feet with vibration absorbers vibrates after an initial impetus at its own natural frequency (also known as resonance frequency). Interference frequencies are generated, for example, by rotating unbalanced masses or lifting movements.

There are a number of devices available on the market that can be used to measure a machine’s vibration frequency. For example, a vibration meter can provide readings for vibrations, acceleration, displacement and temperature.

Effective vibration damping depends on the interference frequency (of the vibration to be damped) and the natural frequency of the machine mounted on damping elements. The greater the frequency difference between the natural frequency and the interference frequency, the better the absorption.

For design engineers, considering vibration does not mean having to create and design bespoke parts for each machine - universally applicable elements for the support of all types of machine are now readily available. Machine feet are another standard component available in a variety of sizes and ideal to use in situations where tensile forces are to be expected.

Happy to help

Providing a safe anti-vibration environment for workers will result in happier workers, increased productivity and reduced chance of accidents. norelem can provide simple measures to reduce exposure to vibration with years of industry experience.

norelem’s experts can help when it comes to providing workplace solutions within the manufacturing and engineering sector, offering advice and recommendations to anyone who needs it.