Huck® Bobtail® from Arconic Fastening Systems - The Next Step in LockBolt Evolution

Designed to overcome inherent weaknesses with standard lockbolts, the BobTail has no pin-tail and as a result of this zero pin-break, no waste material to collect and dispose of or potential corrosion issues post installation. The lightweight, low-noise, low-maintenance tooling, which can be used for both installing and removing fasteners, provides a smooth, shock-free, speedy installation sequence i.e. two seconds for a 16mm diameter fastener - twice as fast as any other large diameter lockbolt on the market. As a result, no torque or impact is transferred to the operator.

BobTail fasteners install in only 2 seconds, up to twice as fast as any other large diameter LockBolt on the market.

High Fatigue Strength Thread Form

BobTail thread form is shallower than a common bolt thread, so there is a larger cross-sectional area to spread out the service load, and fatigue strength increases.

The thread form also has a much larger root radius than a common bolt thread, so stress concentration at the thread root is also reduced, which increases fatigue strength even more.

Maintenance Free

The Huck BobTail 12,14,16, 20mm and 1 inch diameters, after lengthy and vigorous independent testing, has gained the prestigious Allgemeine bauaufsichtliche Zulassungen (German national technical approval) from the world renowned DIBt (Deutsches Institut für Bautechnik) for use in both static and dynamic applications in civil engineering.

Furthermore, the approval concludes that retorque/retension of an installed Huck BobTail LockBolt is not possible, as well as being not necessary, and connections do not require maintenance regarding preload.

Thus joints fastened together by large diameter Huck BobTail LockBolts, within the range specified, are maintenance free.

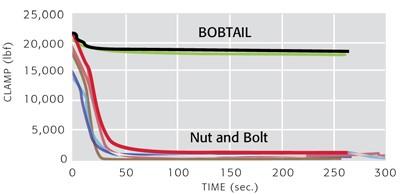

Consistent Clamp

Unlike conventional nuts and bolts, Huck fasteners will not work loose, even during extreme vibration.

Installation Indicator on Collar for Visual Inspection

The swage indicators indent when installation is complete. (12-20mm diameter).

Prior to installation

After installation

Low Installation Noise & No Waste

No pin-tail or pin-break hence resulting in; no material waste, low installation noise and increased corrosion resistance.

Easy to Learn, Shock Free Installation

Eliminates jolts to the operator’s arms and hands.

Unique Helical Lock Groove

Holds pin and collar in place prior to installation.

How to install a BobTail:

1. The BobTail Pin is inserted into the prepared hole of the joint assembly, and the BobTail Collar is placed over the Pin.

2. The Huck Installation Tool Nose Assembly is located onto the annular pull grooves of the Pin. When the tool is activated, a Puller in the Nose Assembly moves the Nose Assembly toward the Collar, causing the swaging Anvil to press on the collar, closing any gap in the joint assembly.

3. At a predetermined force, the Anvil begins to swage the Collar into the lock grooves of the Pin. Continued swaging elongates the Collar and Pin, developing precise clamp in the joint.

4. When swaging of the Collar into the lock grooves is complete, the Tool ejects from the installed Fastener, releasing the Puller from the Pin to complete the sequence. Depending on the type of BobTail Tool used, the ejection cycle will happen either automatically, or when the operator releases the Tool Trigger.