HELICOIL® thread inserts create high-strength, wear-resistant, heat-resistant threads of highest precision by transferring the force from flank to flank into the pilot thread. The reduced diameter of the HELICOIL® Plus in the first thread ensures that the thread insert can be put in like a screw.

The HELICOIL® is used in mechanical engineering and in the electronics, automotive and aerospace industries. HELICOIL® is also applied in gear housings, exhaust systems, engines and satellites, thread reinforcement, repeated installations, maintenance and repair as well as in lights, electrical appliances, hammer drills and printing presses.

HELICOIL® Plus thread inserts comply with a variety of requirements and industry standards, including those in the aerospace industry, and feature other approvals as well as suitability tests, for example, in the field of power plant technology.

Product benefits

- High-strength

- Strong

- Corrosion and temperature-resistant

- Easy to identify even after insertion (due to colour)

- Different versions for every requirement

- Various technical surface finishes available

- Assembly systems, tools and products from a single source

- Available with imperial and metric dimensions and in special versions

Reasons for HELICOIL®

HELICOIL® inserts ensure high-strength threads, transferring forces from flank to flank into the holding thread. This is a system of high reliability for which German and international industrial property rights have been filed and which is available worldwide. HELICOIL® provides thread inserts produced according to consistent material and quality specifications. This technology is the basis of national, aeronautical and military standards. Many leading large-scale users base their manufacturing standards on this system.

Structural component

Wherever low-strength materials (e.g. aluminium, magnesium alloys and fibre-reinforced plastics) are used, HELICOIL® is indispensable for thread reinforcement. This applies particularly to the aerospace industry, mechanical and plant engineering, the automotive industry and electrical and medical engineering. Thread reinforcement prevents wear of the threaded hole - even after frequent use. HELICOIL® allows miniaturisation and lightweight construction in the development of serial parts. The required strength is provided by thread reinforcement with HELICOIL®.

Rejects recovery and thread repair

HELICOIL® thread inserts are internationally approved for the economical and permanent repair of damaged and worn out threads. Apart from repair of valuable individual components, the possibility to return and salvage large volume components which have been rejected due to faults in the thread production is of major importance.

ECO kits

Now, Böllhoff has launched a new economy offer called ECO kit. The ECO kit can be used in numerous situations. It is a quick and economical solution to any type of thread repair, regardless of application. HELICOIL® ECO kits contain all necessary tools and inserts and together by step by step instructions for use.

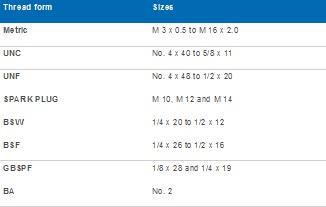

There is a huge range of different thread forms and sizes covered by the ECO kits from 2BA to M10 and Spark Plug threads too!

HELICOIL® plus thread repair kits

HELICOIL® plus thread repair kits allow easy installation of a new thread in only a few steps. Kits contain all necessary tools and HELICOIL® plus inserts and together by step by step instructions for use. The reduced first coil of the HELICOIL® plus insert further simplifies the repair.