When dispensing small amounts of two-part adhesive or other materials, two key considerations include whether the material is mixed correctly, and the accuracy of the amount dispensed.

There is a growing demand for the precise metering, mixing and dispensing of small amounts of two-part technical materials like adhesives, potting compounds, encapsulants and sealants — including electrically or thermally conductive variants. This is driven by manufacturers in the electronics, medical device and automotive industries requiring increased functionality in seemingly ever smaller formats. In parallel, these engineers are looking for high accuracy material application in a robust and consistent process. They want precise quantities, uniformly mixed in the correct ratio, applied in exact locations.

Two-part formulations can offer superior cured performance but can be difficult to process. A typical method involves weighing out the constituent parts, mixing in a container with a spatula and loading into a dispensing syringe barrel for application. There may be a vacuum degassing or centrifuge step to remove entrapped air. Some suppliers offer respite from this procedure by providing their materials in a pre-mixed, degassed and frozen packaging. However, there are extra costs associated with shipping and storage, which are partly offset by the material being ready to use after thawing.

Once the material is mixed (or thawed), curing starts and the material’s viscosity will start to increase. The amounts dispensed directly from the syringe or through a dispensing valve using air pressure will vary with viscosity change and it is difficult to maintain an accurate deposition. Moreover, the mixed material will have a limited working life, and this can lead to waste as it cures too much to still be usable.

One solution is to use a metering and mixing machine, where measured amounts of material are fed through a mixing nozzle and can then be dispensed directly to the part. Systems operating with gear pumps or piston pumps are readily available but are more suited to larger material quantities, such as potting transformers.

If the requirement is for the application of a few millilitres or even fractions of a millilitre, then another technology is considered — metering and mixing based on progressive cavity pumps. The pump comprises a specially shaped rotor inside an elastomeric stator, forming a series of tapering and overlapping spaces or pockets which progress through the pump as the rotor is turned, producing a pulseless material flow. Flow rate is directly proportional to the rate of rotation. Input pressure and material viscosity have no impact on the output of the pump and the system will achieve true volumetric output based on positive displacement. Dispensing at the point of mixing precludes variability due to viscosity change and reduces wastage. Materials may be purchased in larger package sizes, which can reduce purchasing costs.

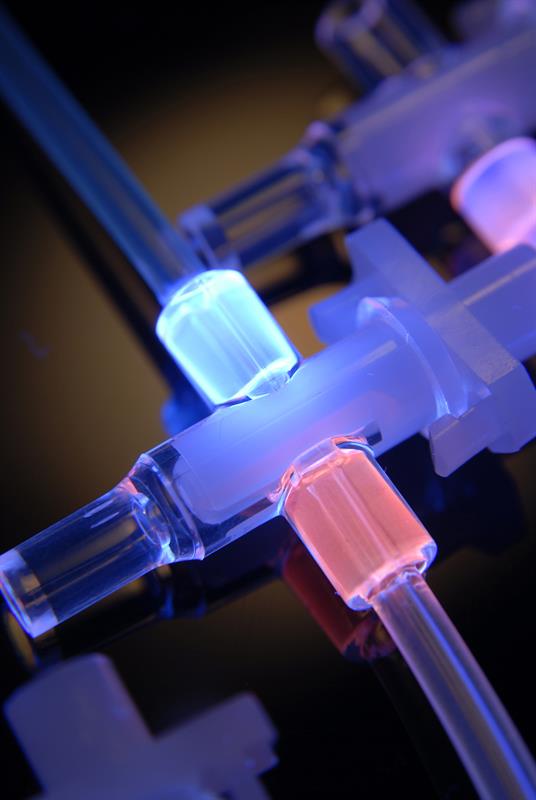

One example of such technology is the preeflow eco-DUO, a high precision volumetric metering, mixing and dispensing unit, which integrates two preeflow eco-PENs through a manifold and static mixing nozzle. Suitable for a wide range of materials with viscosities from water up to pastes, it enables flow rates from 0.1 to 32 ml/minute. It also offers a mixing ratio of up to 10:1, which can be changed dependent on the project. The variable mix ratio means that unlike many other systems, the user can reconfigure it for different materials, rather than sending it back to the system manufacturer for modification.

The operator can control the flow to fine limits and calibrate the controller to the system for a repeatable output. It is readily integrated into automation to ensure that as well as dispensing volume, positioning is extremely repeatable.

One customer success we have seen is with BPR Medical, which manufactures a valve to extinguish fires in the line between an oxygen concentrator and the user’s mask or nasal cannula ─ a lifesaving technology. The customer was dispensing a two-part epoxy to bond two halves of the valve’s body in a precise repeatable volume, metered and mixed correctly, to achieve a bond integrity to meet conformance for CE marking under the Medical Device Directive. Testing revealed that the preeflow eco-DUO would provide an appropriate solution. The system has proven itself in their production line, with its dispensing accuracy also providing a rapid return on investment through a 16% material savings per part.

When metering, mixing and dispensing small amounts of two-part materials, consistent mixing and precise application to the correct location can impact a project’s success and provide significant cost savings over the lifetime of production.

UV curing for medical devices  Medical device applications which use UV curing adhesives include needles and cannulas, reservoirs, tube sets and catheters. Using the right technology can result in increased production efficacy and productivity. “When assembling a medical device, it is critical that processes are reliable, consistent and are able to be validated,” says Peter Swanson, managing director, Intertronics. “For bonding parts, UV light curing adhesives perform well against these criteria. They are single part systems and come in a range of viscosities, facilitating precise, repeatable dispensing, both in quantity and location. Curing is fully completed in seconds and within a controlled process window, meaning that immediate on-line quality assurance checks are possible.” Traditionally, mercury-based arc lamps were used for UV curing as they generate a broad spectrum of UV light. LED-based UV lamps have grown in popularity, offering several benefits over broad spectrum lamps. For example, instead of warm up and cool down periods, LED-based UV lamps are instant on-off, which uses much less power. They also have no bulbs to replace and generate less heat, allowing manufacturers to work with more sensitive substrates. “The choice of adhesive will be substrate dependent,” adds Swanson. “An adhesive which adheres well to PVC may not adhere well to stainless steel. Ensuring good adhesion to all substrates may be even more challenging in medical device manufacturing, where some less common plastics are used, e.g. polyether ether ketone. In some cases, plasma surface treatment can be used to improve adhesion to low surface energy polymers.” LED-based UV curing lamps are available in 365-405nm wavelengths, and power outputs sufficient for even high-speed production. They range from lamps generating spots a few millimetres in diameter to large area floods, and can be hand-held, configured for benchtop use, or designed for use in automation or conveyors. |