Make the smart fastener selection

When designing a machine to function in an Industry 4.0 factory you must take into consideration the functionality of the machine, the environment it has to operate in and the cost of maintaining and building the machine.

Smooth operators

Precision is increasingly important. You can specify Linear Motion and Telescopic Slides to ensure machine movement is smooth and accurate. JET PRESS works closely with Accuride to provide steel, stainless steel and aluminium slides for plant equipment in factories.

These slides are made from engineering grade materials and deliver outstanding performance even in tough conditions. For instance, the grinders that are used to keep mower blades sharp in most of the world’s top sporting venues use Accuride slides from JET PRESS.

Movers and shakers

Movers and shakers

Vibration is another big challenge when you design a machine. From Vibration Dampened Machine Mounts to Palnuts and Lock Washers that keep nut and bolt assemblies securely in place. JET PRESS provides a huge range of fasteners and hardware helping you to plan and design a machine protected from vibration.

Managing machinery

A crucial part of Industry 4.0 is about using data and making machines talk to each other – the internet of things (IoT). That means you will have to deal with data cables along with high voltage cables, hydraulic hoses and coolant hoses running in all directions.

Sometimes a designer will need a bespoke solution, maybe even pre-assembled. But a low cost, off the shelf solution can often be found.

Fasteners you can unfasten

Machines need to be maintained. That means fasteners have to be unfastened. Access usually means removing things like panels and guards, so good maintenance solutions need to be designed in.

For heavy guards, slides or gas struts can be used. For smaller panels, bolts or screws may be the right solution, but not always. Bi-Fix Quarter Turn Fasteners for access panels are very easy to install, and maintenance staff can open them with just a quarter turn. At the design stage this might not seem very important, but because these fasteners stay attached to the panel there’s no risk of fasteners being lost, or worse still, dropped into the machine.

Assembling the machine

Most machines are significant capital items, so the unit cost of a fastener may not appear to be of huge importance. But it doesn’t make sense to pay more than you have to.

One area where specifying the right fastener can make a real difference is in the assembly process. The

team at JET PRESS worked with a machine designer on a bespoke cable and hose management component. It was designed in a way that made assembly quicker, easier and therefore less expensive.

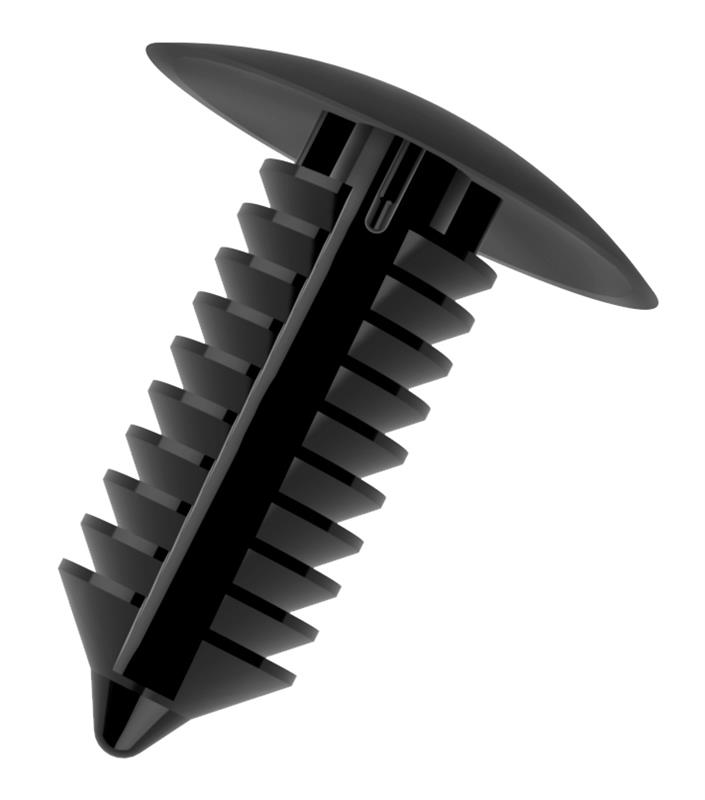

The machine that is designed will exist as part of a system of machines, and the adaptability of that system is at the core of Industry 4.0. Specifying the right fastener for anchor points used for attachments can make a big difference and the choice from JET PRESS includes Lug Nuts, U Nuts, Weld Nuts and Plastic Rivets along with Drive Rivets, Scrivets, Fir Tree Buttons, W buttons and Self-Tapping Screws like the Pan Head Self-Tapping Nylon Screw – to name a few – for general assembly.