The plastics industry is a great example of an area currently undergoing transformation, replacing hydrocarbon by-products of the oil industry with bio based raw materials. This helps to reduce our reliance on fossil fuels, and the environmental impact their extraction and use have on the planet.

Bio-based materials are made from once-living organisms. Examples include:

- PLA plastic made from algae

- Fabric made from bamboo fibres or cellulose made from fruit peel

- Polymeric materials made from coconut shells

- Wheat/potato or corn based plastics

As well as being able to be farmed sustainably, these materials are also biodegradable so they can be composted and do not add to the long-term plastic waste problem that future generations will have to deal with.

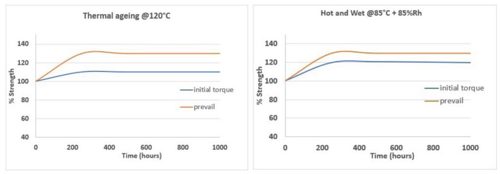

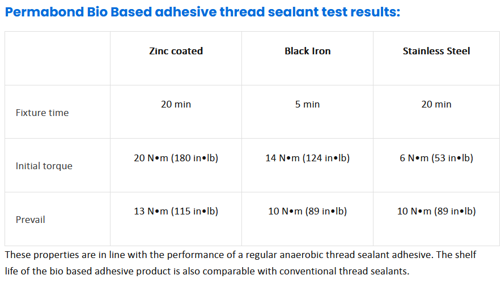

Many bio-based materials are suitable for making plastics and can even be incorporated into adhesive formulations. Permabond has been exploring the use of bio-based materials in adhesive formulations. It has successfully developed a thread sealing adhesive that contains over 50% bio-based material. The product has shown performance similar to regular thread sealing grades, providing 100% seal on threaded metal pipe joints and excellent thermal and environmental resistance (Table 1).

These properties are in line with the performance of a regular anaerobic thread sealant adhesive. The shelf life of the bio based adhesive product is also comparable with conventional thread sealants.

The Permabond bio based adhesive thread sealant is formulated and tested in accordance with ISO16620:2015, which specifies the general principle and calculation for determining the percentage content of bio based material in the formulation. The calculations are from the amount of carbon mass of each constituent in plastic products. ISO16620:2015 relates to plastic products and plastic materials, polymer resins, monomers, or additives, which are made from bio based raw materials.

Key Features & Benefits of Permabond Bio based adhesive thread sealant:

- >50% bio based content – ideal for improving sustainability in product design

- Thread sealant for sealing metal threaded pipe joints – seals against liquids and gases

- Can also be used for threadlocking coarsely-threaded nuts and bolts

- Excellent environmental resistance

- Shelf life and storage = same as standard anaerobic

- Reactivity = similar performance to standard thread sealant

- Strength = in line with normal thread sealant performance

- Application process = same as normal anaerobic thread sealant

Permabond argues that this is a great step in the right direction to help improve sustainability and, ultimately, a better future for the environment and the next generation.